How To:

Install a Double Hung Wood Window Screen

Before You Begin

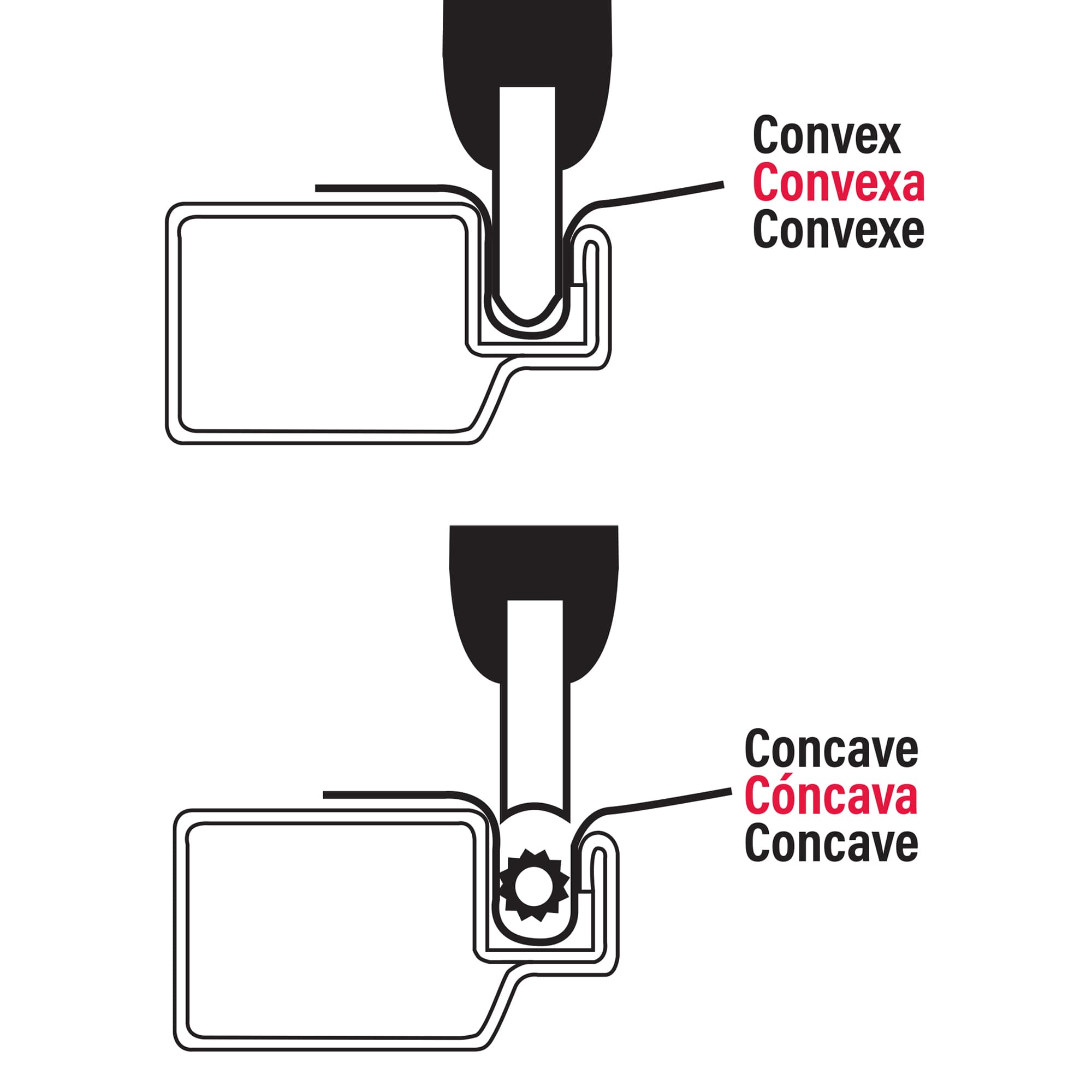

Determine the type of window you have. The required steps for replacing your window screen will change depending on the type you have. This is also true for the type of screen you have.

These are the materials and tools that will be required to install your window.

Materials

- Screen Frame

- Screen cloth (aluminum or fiberglass)

- Screen retainer spline

- Plastic Corners

Tools

- Hacksaw

- Box Cutter

- Tape Measure

- Screening Tool

Before you begin cutting the screens to size, take a quick look at your window and see if they match any of the images below. If your window matches the image for a double hung wood window, continue reading; however, if it's a casement window or a sliding window:

Click on the button below the image of the window that looks like yours. You will be taken to the corresponding instruction manual page.

Double Hung Wood Window Screen Installation

Step 1: Measure the Screen

Step 2: Cut the Frame

Measure the existing screen or screen location. Deduct 1-1/2" from each measurement, then square cut the frame with a hacksaw (we recommend a fine-tooth hacksaw). When the corners are installed (Step 3), they will fill the overall dimension requirements.

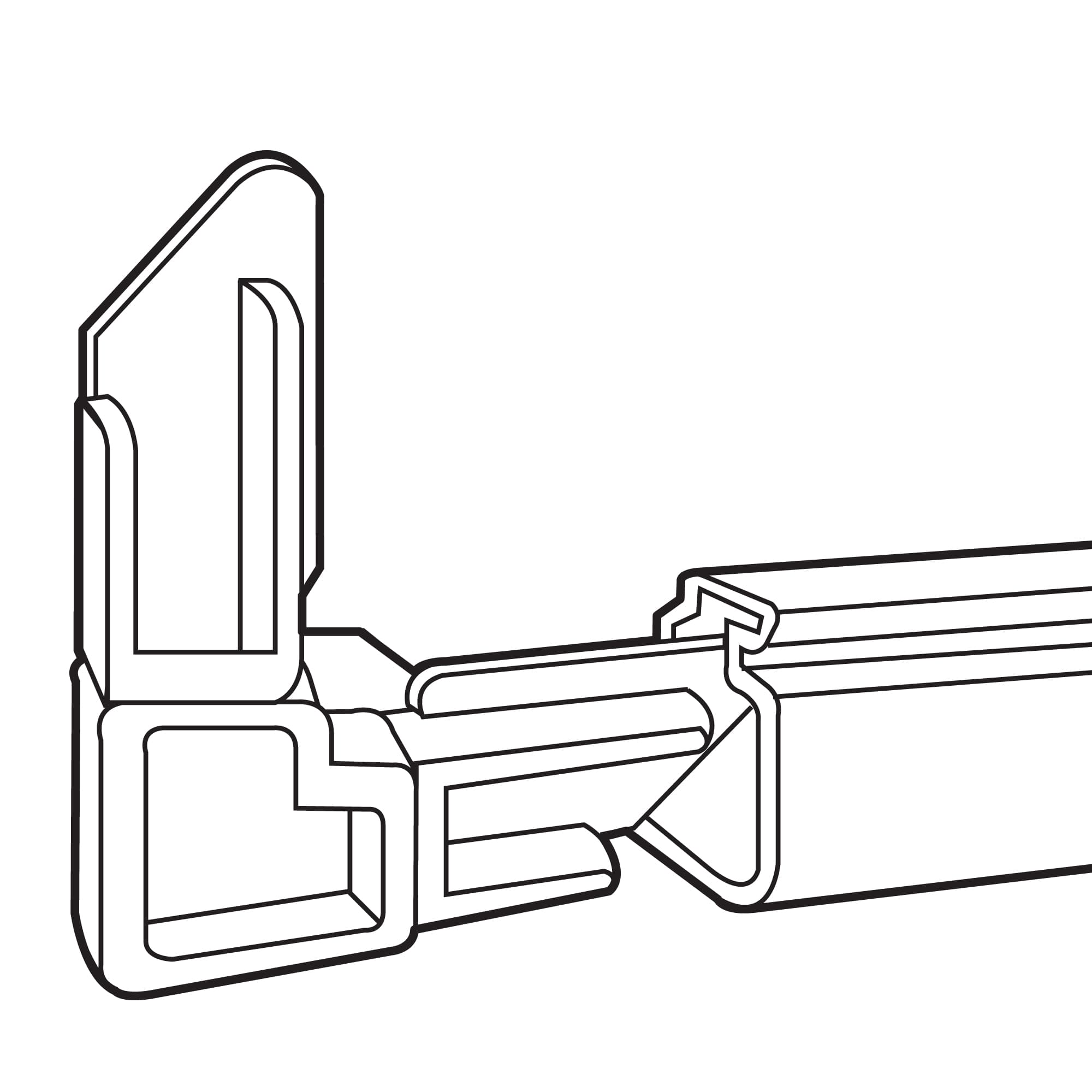

Step 3: Assemble the Frame

Insert the corners into the short lengths first, then insert the exposed corner leg into the long lengths. Lightly tap the corners into place. Check the assembled frame for squareness.